PRODUCT INTRODUCTION

Alloy with Both Heat and Wear Resistance

TNE Alloy

- Wear

Resistance - Oxidation

Resistance - Heat

Resistance - Cermets

TNE Alloy is a cermet which is mainly composed of titanium carbonitride with excellent oxidation resistance. Compared to general cermet, it has superior fracture toughness and contributes to longer tool life.

Properties

| Grades | Specific Gravity |

Hardness (HRA) |

Transverse Rupture Strength (GPa) |

Fracture Toughness (MPa・m½) |

|---|---|---|---|---|

| TNE40 | 6.00 | 89.0 | 2.5 | 15 |

※All data shown are typical values, not guaranteed values.

※We will not compensate any loss and damage caused by using all data.

※We reserve the right to modify the data due to technical progress.

Characteristics

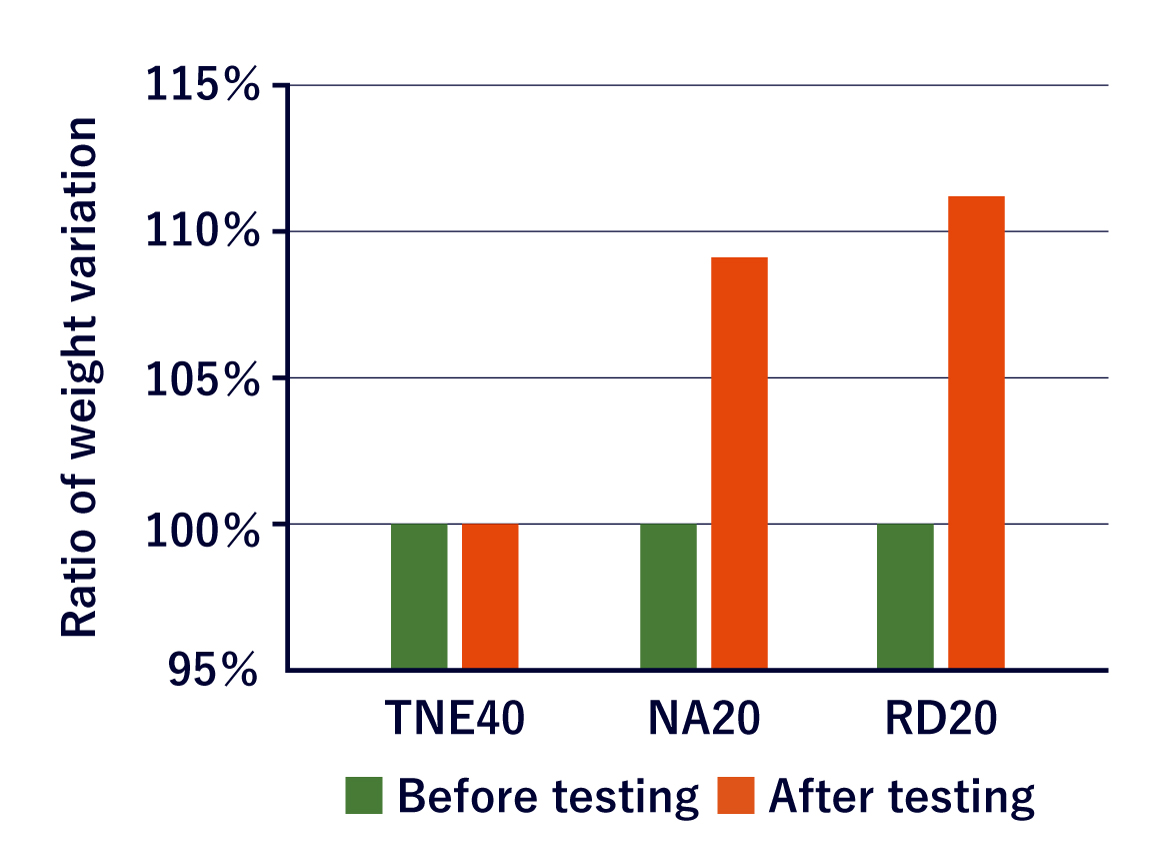

Comparison of oxidation resistance

-

- Ratio of weight variation after holding at 900°C for 1 hour in air atmosphere

- Regarding oxidation weight gain, it is about 11% for RD20 and about 8 % for NA20, but it is about 0.1% for TNE40. Almost no oxidative weight gain is observed.

-

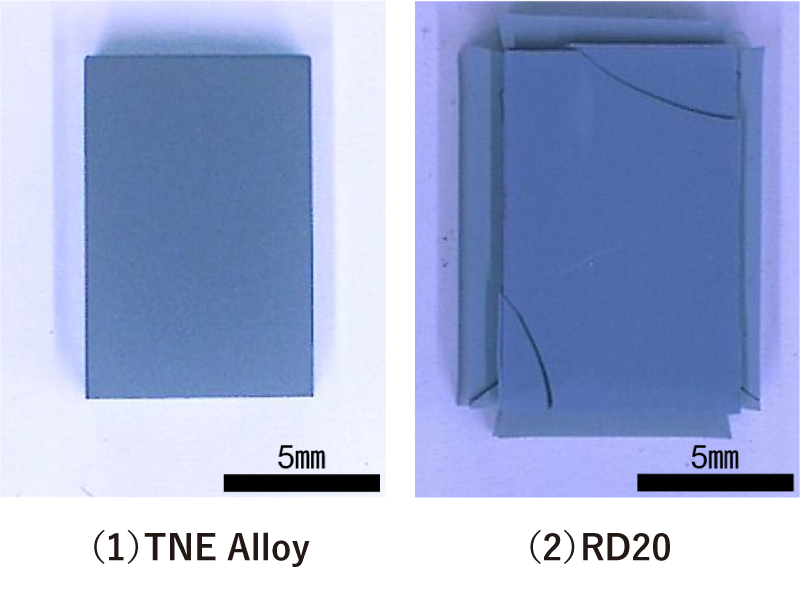

- Surface condition in the atmosphere retaining 900℃x1h

- RD20 forms oxidized phase on each of the six faces after retaining. On the other hand, TNE Alloy is slightly changed color, but is no oxidated phase such as RD20.

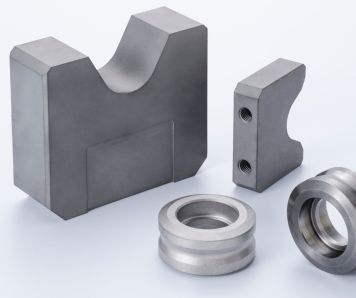

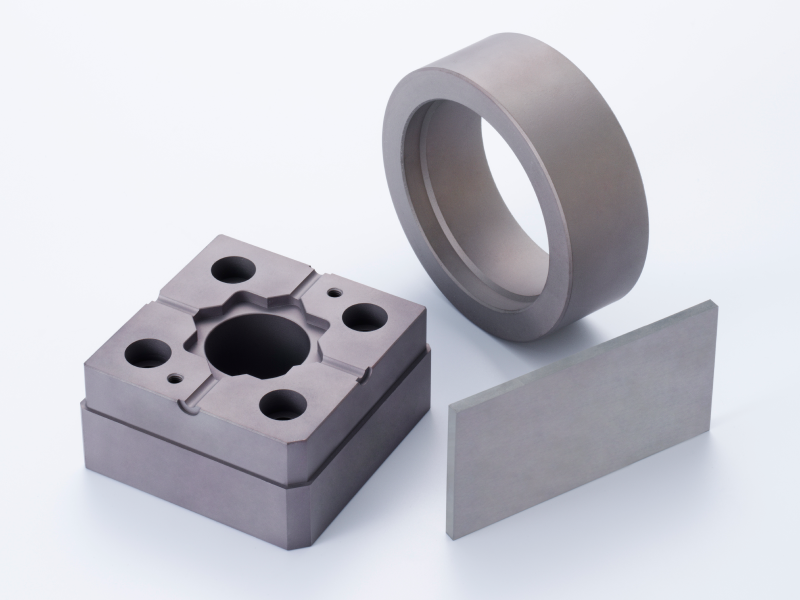

Typical Applications

- Dies