PRODUCT INTRODUCTION

Low Friction Cemented Carbides with Both Wear and Chipping Resistance

PRF Series

- Corrosion

Resistance - Wear

Resistance - Seizure

Resistance - Chipping

Resistance

PRF Series exhibits particularly excellent wear resistance by adopting ultrafine grained WC. Furthermore, it also excels in seizure resistance by adding low-friction to RF Series while retaining the original characteristics. It is suitable for applications which require wear resistance or strength, such as progressive dies and blanking punches.

Properties

| Grades | Grades Classification Symbol | Specific Gravity |

Hardness (HRA) |

Transverse Rupture Strength (GPa) |

Fracture Toughness (MPa・m½) |

|---|---|---|---|---|---|

| PRF9N | VF-30 | 14.55 | 91.5 | 3.0 | 13 |

| PRF14N | VF-40 | 14.00 | 90.0 | 3.5 | 15 |

※All data shown are typical values, not guaranteed values.

※We will not compensate any loss and damage caused by using all data.

※We reserve the right to modify the data due to technical progress.

Characteristics

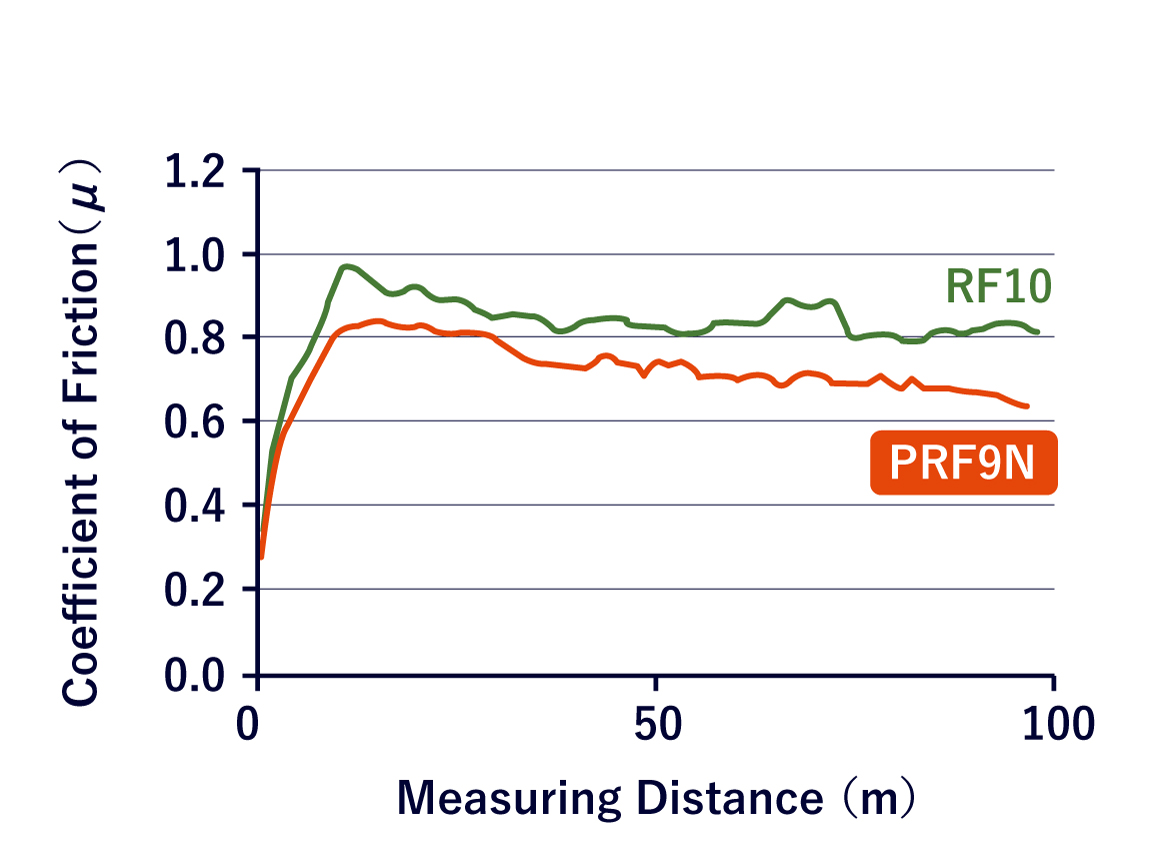

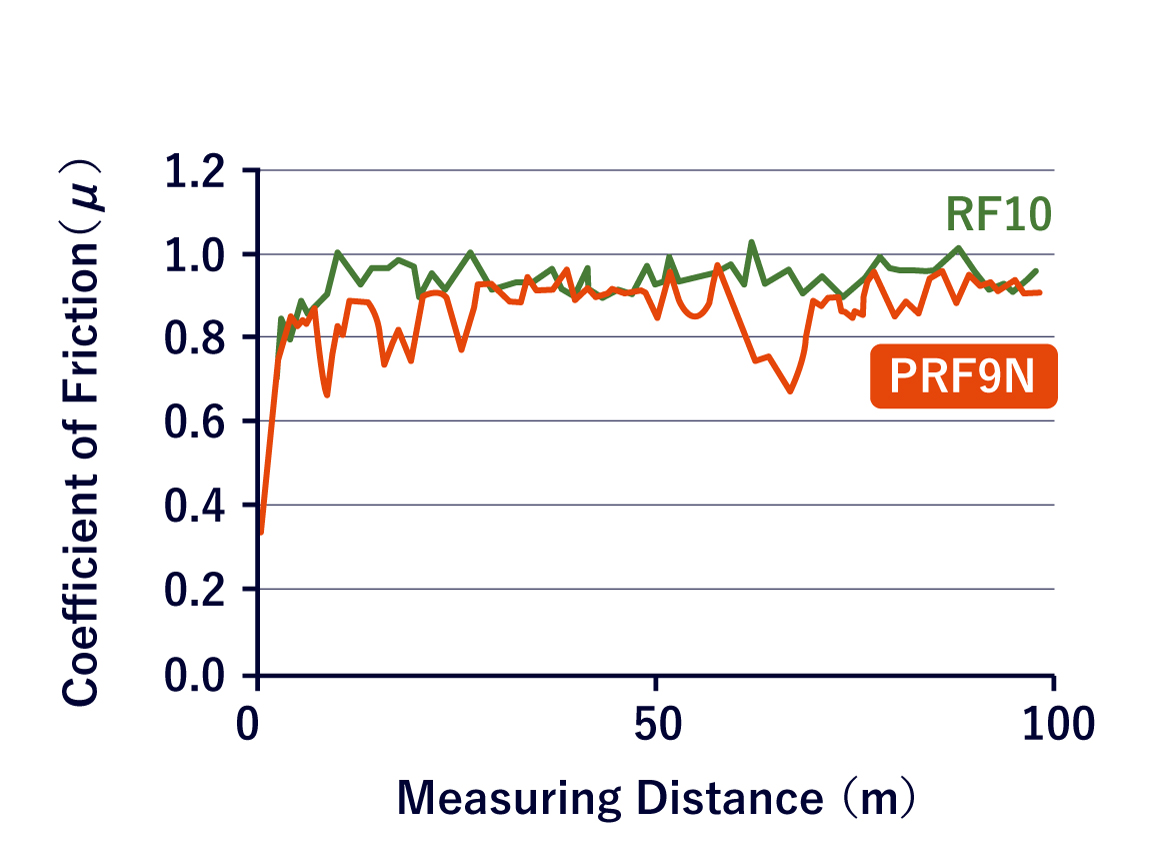

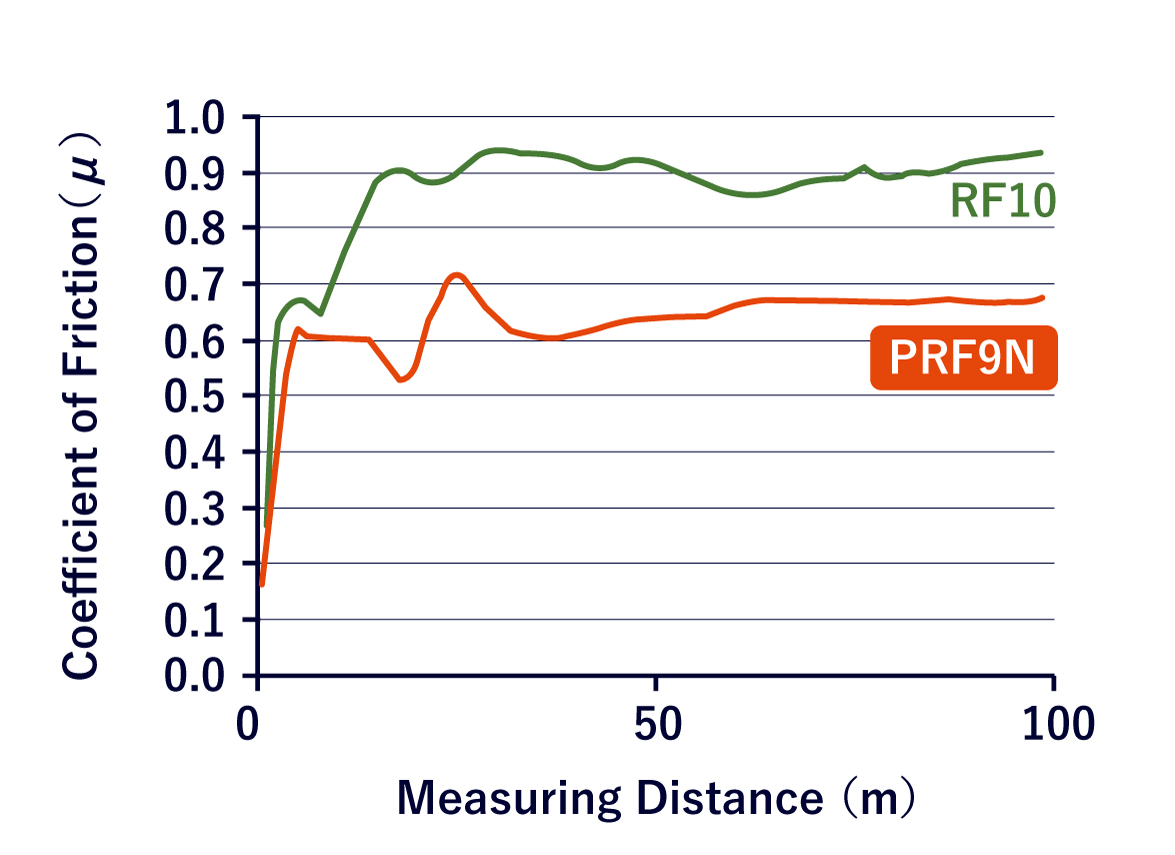

Coefficient of Friction Comparison Result between PRF Series and RF10

-

- Coefficient of Friction for Copper Alloy

- The coefficient of friction of PRF9N is lower than that of RF10.

-

- Coefficient of Friction for Aluminum Alloy

- Although there are some areas where the values are similar, overall PRF9N has lower friction comparing to RF10.

-

- Coefficient of Friction for SUJ2

- The coefficient of friction of PRF9N is lower than that of RF10.

-

- PRF14N Microstructure

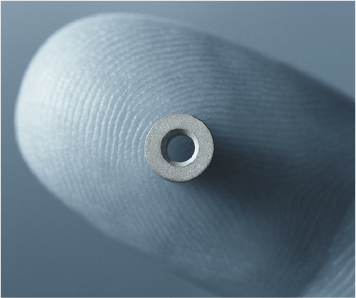

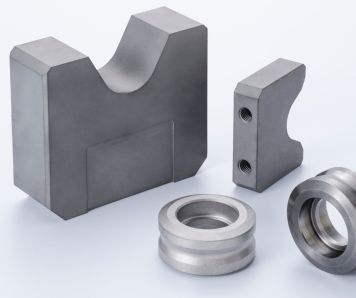

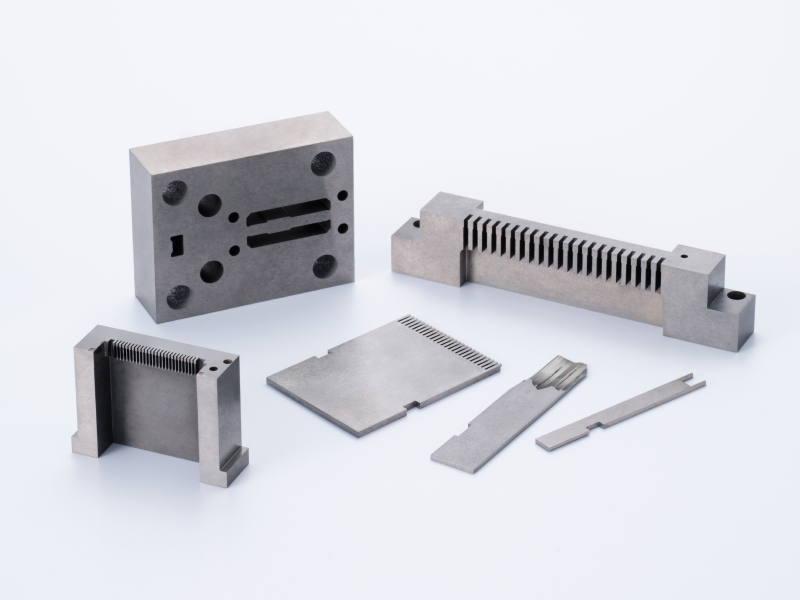

Typical Applications

- Dies

- Punches

- Die

- Bushes