PRODUCT INTRODUCTION

3D-printed Cemented Carbides

Cemented Carbides by AM

- Corrosion

Resistance - Impact

Resistance

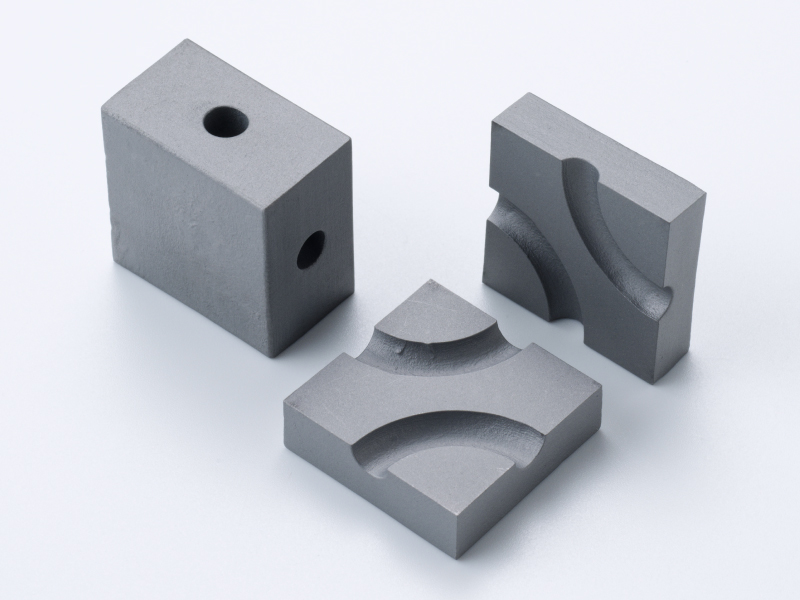

Sanalloy’s additive manufacturing technology (Additive Manufacturing:AM) has achieved to produce hollow structure or complex three-dimensional shapes which are difficult to process by conventional forming technique such as powder molding or machining.

Properties

| Grades | Specific Gravity |

Hardness (HRA) |

Transverse Rupture Strength (GPa) |

Fracture Toughness (MPa・m½) |

|---|---|---|---|---|

| REA65 | 13.90 | 87.0 | 3.4 | 21 |

| REA75 | 13.40 | 85.5 | 3.2 | 25 |

| REA85 | 13.00 | 83.5 | 3.0 | 28 |

| RV66 | 13.95 | 86.0 | 2.8 | 25 |

| RV76 | 13.55 | 84.5 | 2.7 | 27 |

| RV86 | 13.25 | 83.5 | 2.7 | 28 |

| RL89 | 13.50 | 83.0 | 2.5 | 30 |

※All data shown are typical values, not guaranteed values.

※We will not compensate any loss and damage caused by using all data.

※We reserve the right to modify the data due to technical progress.

※The corresponding grades will be frequently updated.

Shape

It is possible to manufacture Cemented Carbides in complex shapes, such as a flower shape with multiple overlapping petals or a QR code with minute irregularities.

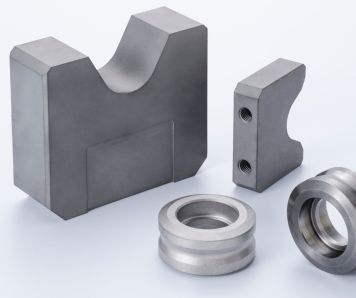

3D-printed Cemented Carbides Products

-

- Piping Parts

- Two blocks on the right side is the cross sections of a left block. The hole has curved internal structures.

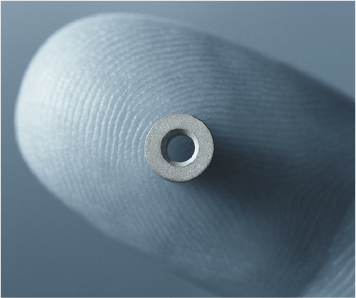

Corresponding Size

Less than 35mm×35mm×90mm

※Please feel free to contact our sales for further information.

Typical Applications

- Dies