Characteristic Value

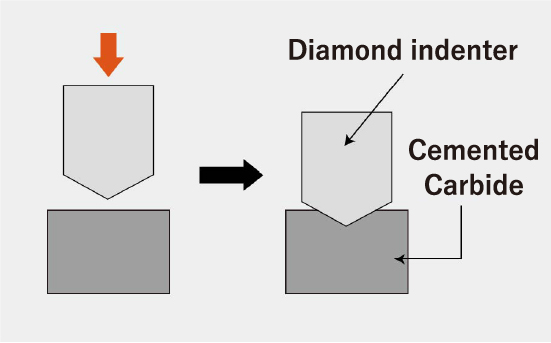

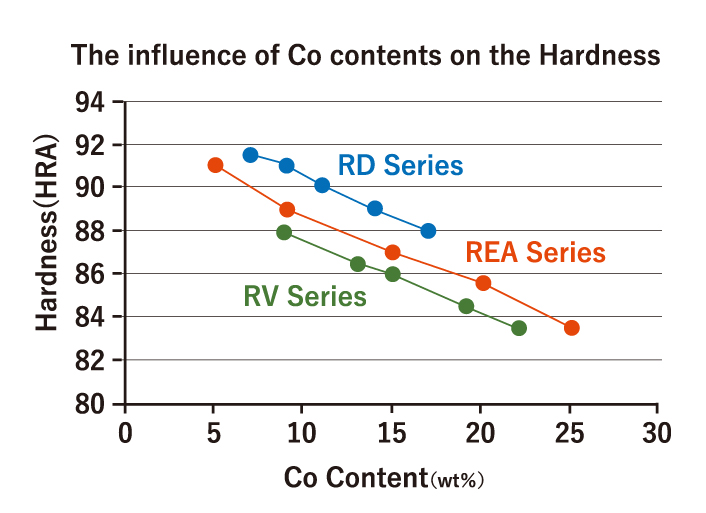

Hardness

Hardness refers to the resistance a material exhibits against deformation when subjected to force. A higher hardness value indicates lower susceptibility to wear and tear.

The hardness is higher when Co contents decrease. The carbide with smaller WC grain size has higher hardness.

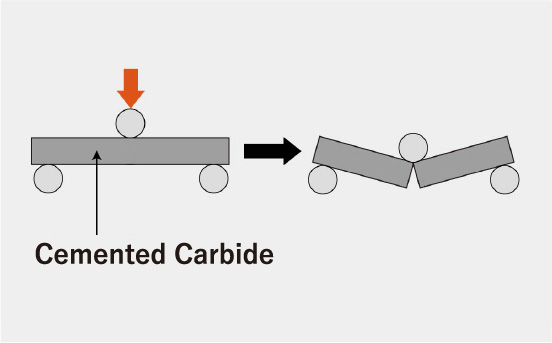

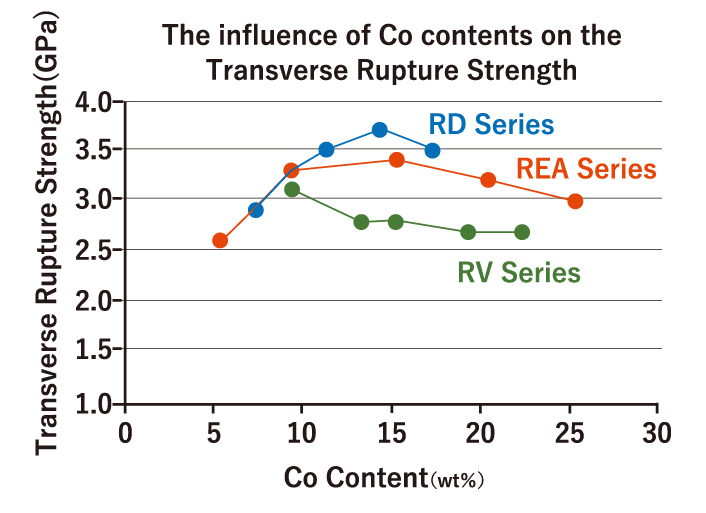

Transverse Rupture Strength

Transverse rupture strength (TRS) represents the ability to withstand bending stress without breaking. A higher value indicates greater resistance to fractures caused by bending.

The TRS shows the biggest value when Co contents is 15wt%. The carbide with smaller WC grain size has higher transverse rupture strength.

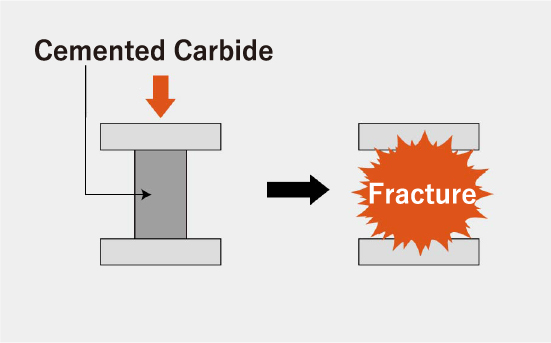

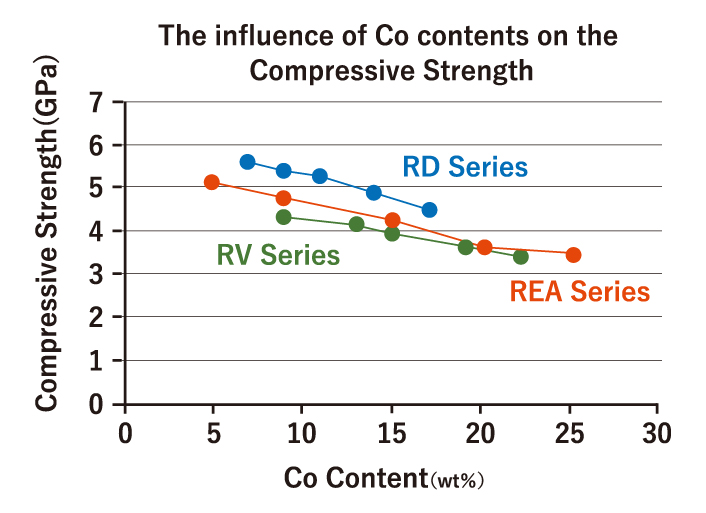

Compressive Strength

Compressive strength refers to the resistance to failure under compressive stress. A higher value indicates a greater resistance to fractures resulting from compression.

The compressive strength is higher when Co contents decrease. The carbide with smaller WC grain size has higher compressive strength.

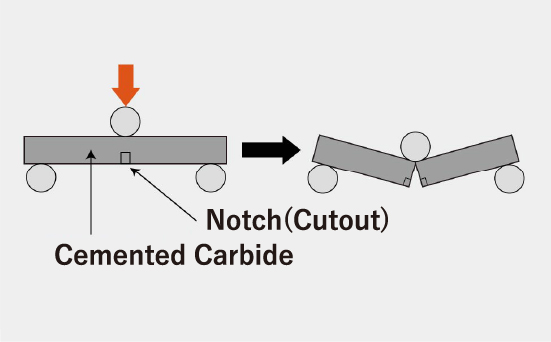

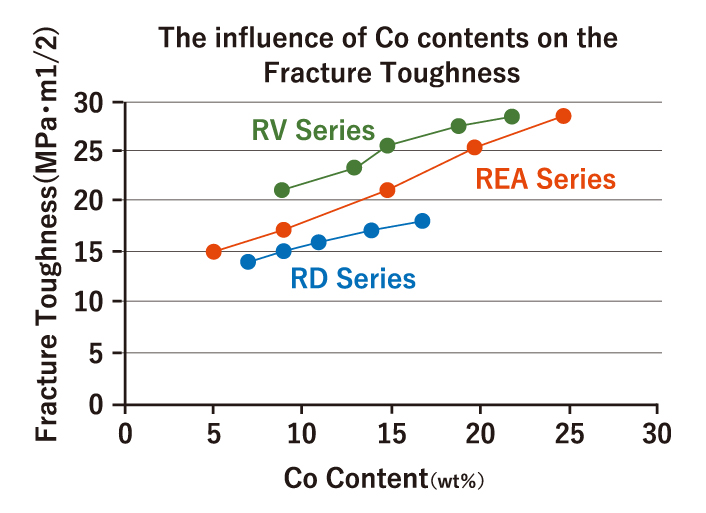

Fracture Toughness

Fracture toughness measures the energy needed for fracture. A higher value indicates greater resistance to crack propagation.

Fracture toughness increase depend on Co contents. The carbide with bigger WC grain size has higher fracture toughness.

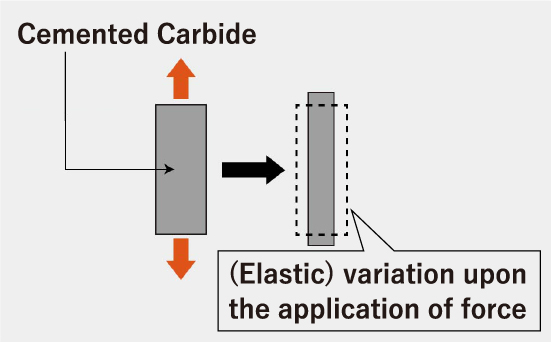

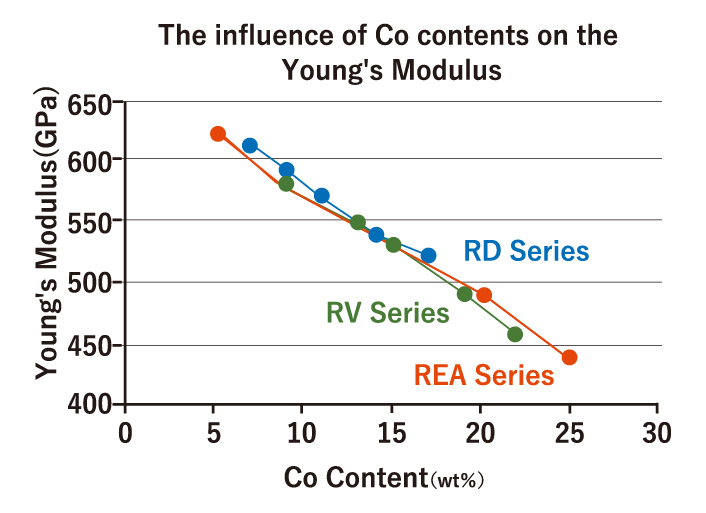

Young's Modulus

Young's modulus indicates the relationship between strain and stress in the direction of compressive or tensile stress within the elastic range. A higher value implies that the material is less prone to elastic deformation.

The young's modulus is higher when Co contents decrease. Young's modulus changes independent on WC grain size.

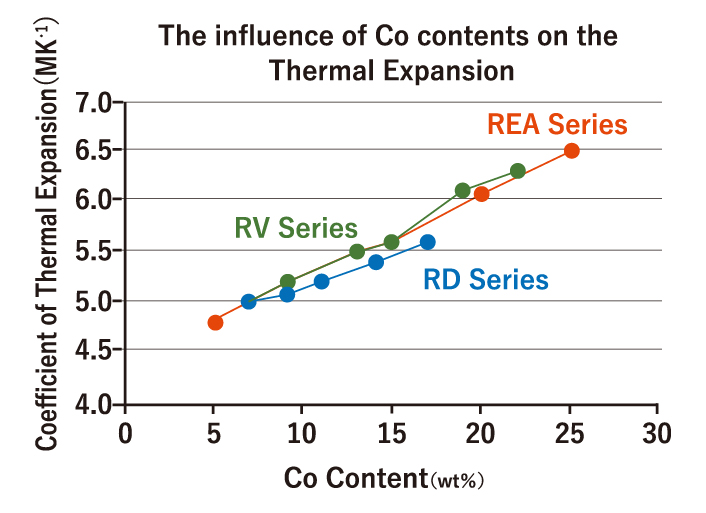

Coefficient of Thermal Expansion

The coefficient of thermal expansion indicates how much a material expands when the temperature increases. A smaller coefficient of thermal expansion means that the material undergoes less deformation with temperature changes.

The coefficient of thermal expansion is higher when Co contents decrease. Coefficient of thermal expansion changes independent on WC grain size.