FAQ

FAQ

What are cemented carbides?

- Q.What is the difference between cemented carbides and steels?

- A.

The main distinction lies in hardness, as cemented carbide surpasses steel in this aspect. Additionally, its Young’s modulus is roughly three times greater, and its coefficient of thermal conductivity is approximately half that of steel. Consequently, cemented carbides, prized for their exceptional wear resistance, minimal thermal and elastic deformation, find extensive application in forging dies demanding precise dimensional accuracy and other similar requirements.

- Q.What are the applications of cemented carbides?

- A.

Primarily utilized for cutting tools designed for metalwork and molds essential for deformation processing.

- Q.What are the advantages of cemented carbides?

- A.

Cemented carbides can significantly prolong the lifespan of tools and molds owing to its outstanding wear resistance.

- Q.At what temperature do cemented carbides begin to oxidize?

- A.

The cobalt oxidation begins at approximately 300℃ and the WC oxidation rapidly processes from approximately 600℃.

This causes the strength reduction of alloys and leads to the factor of damage.

Shapes and Appearance

- Q.Why do grades exhibit varying colors?

- A.

The color is determined by the binder metal content. Grades with higher binder metal content typically exhibit a lighter gray hue.

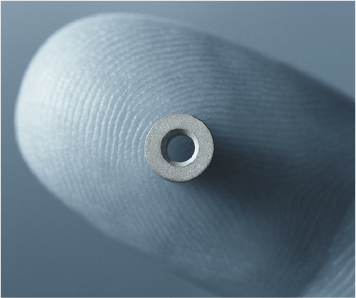

- Q.What is the maximum size that cemented carbides can be processed into?

- A.

The maximum sizes we can process vary depending on factors such as grades, round shape (ODxLxID), block shape (WxLxH), and machining specifications. For more detailed information, please don't hesitate to reach out to us.

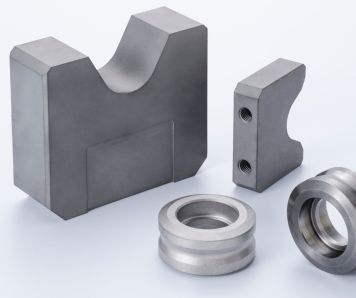

- Q.There may be complex processing involved, but how far can you process?

- A.

The possible machining shapes vary depending on factors such as grades, sizes, shapes, etc. Please contact our sales department for details. We can also provide machining services based on supplied dat

Grades Selection

- Q.Which cemeted carbides are suitable to prevent seizure?

- A.

The affinity of cobalt in cemented caribides is the major factor of seizure.

To privent it, grades which contain less cobalt or fine graied WC are more likely to chosen, however, the brittleness is also a subject because of the low toughness.

As a countermasure, P Series (low-friction cemented carbides) which excels in seizure resistance is also lined up.

Please don’t hesitate to reach out to us.

Heat Treatment

- Q.Can all products be processed HIP?

- A.

We process HIP for all produts.

The low-pressure HIP is performed for the materials which do not require high-pressure.

Process and Surface Treatment

- Q.What is cemented carbide processed with?

- A.

It is performed through grinding using diamond abrasive stones or through electrical discharge machining using (EDM) wire or electrodes.

- Q.Can cemented carbide be coated?

- A.

Certainly. Coating methods include CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition), both of which have demonstrated efficacy.

Main disadvantages

- Q.What is porosity?

- A.

Pores, also known as "voids", refer to empty spaces within the alloy and constitute a material defect. The presence of pores in the alloy can lead to decreased properties such as hardness and transverse rupture strength resistance.

- Q.What is the η phase?

- A.

While the main components of cemented carbides are WC-Co, an excess or deficiency of carbon (C) can lead to brittleness. The η phase refers to the precipitation of complex carbides (W3Co3C) within the alloy when carbon is in short supply. This results in a decrease in properties such as fracture resistance and compressive strength of the alloy.

Handling

- Q.What are the precautions when handling cemented carbides?

- A.

Cemented carbides can fracture due to impact or dropping. Please carefully inspect the product for any missing parts, cracks, or other abnormalities when unpacking.

- Q.Is cemented carbide susceptible to corrosion?

- A.

Yes, the cobalt, acting as the binder metal in cemented carbides, reacts with water and undergoes dissolution. When exposed to a high-humidity environment over time, the surface of mirror-finished cemented carbides may develop cloudiness. This cloudiness arises from the leaching of cobalt out of the cemented carbides due to condensation.

- Q.What are the environmental and health impacts?

-

A.

Please refer to the Safety Data Sheet (SDS).